2026 How to Conduct Effective Catalyst Testing Techniques?

In the dynamic world of chemical engineering, effective catalyst testing is paramount for optimizing reactions and enhancing efficiency. According to the latest report by the Catalyst Testing Society, approximately 30% of catalyst performance failures are linked to inadequate testing methods. This highlights the necessity for robust protocols in catalyst testing to ensure reliable results.

Industry expert Dr. Emily Carter stated, "Thorough catalyst testing is the backbone of successful industrial processes." Her insights underscore the critical role that strategic testing plays in both academic research and commercial applications. As companies strive to meet growing environmental regulations, refining testing techniques becomes even more crucial.

However, the field is not without challenges. Many researchers still rely on outdated practices that may not yield accurate assessments. A careful evaluation of current methodologies is essential for improvement. Emphasizing innovative techniques can lead to breakthroughs in catalyst performance, benefiting a range of industries from renewable energy to petrochemicals.

Understanding the Importance of Catalyst Testing in Chemical Processes

Catalyst testing is vital in chemical processes. It determines how effectively a catalyst speeds up reactions. The right technique can enhance yields and reduce costs. Without proper testing, a catalyst may underperform or fail entirely. This could lead to product losses and increased waste.

Many methods exist for testing catalysts. Some emphasize activity, while others focus on selectivity. Temperature, pressure, and reactant concentrations play significant roles. It is crucial to replicate actual industrial conditions for accurate results. Some experiments may yield unexpected outcomes. Factors like impurities can skew results. This unpredictability necessitates continuous reflection and improvement in testing methods.

Understanding catalyst efficiency can transform chemical production. If testing fails to identify the best catalyst, processes may become inefficient. Organizations must commit to refining their approaches. Innovation in testing techniques can lead to breakthroughs. Embracing trial and error, even when results aren't ideal, can drive progress. Each step in testing is a learning opportunity.

2026 How to Conduct Effective Catalyst Testing Techniques?

| Testing Technique | Description | Key Parameters | Application | Advantages |

|---|---|---|---|---|

| Activity Testing | Measures the rate of reaction catalyzed by the catalyst. | Reaction rate, Temperature, Pressure | Used in various catalytic reactions. | Quick feedback on catalyst efficiency. |

| Selectivity Testing | Determines how selectively a catalyst converts reactants to desired products. | Product distribution, Conversion percentage | Critical for fine chemical synthesis. | Helps in product purity improvement. |

| Stability Testing | Assesses the long-term durability of catalysts under reaction conditions. | Time on stream, Deactivation rate | Applicable in industrial catalytic processes. | Ensures economic viability of the catalyst. |

| Kinetic Studies | Focuses on determining the reaction kinetics with the catalyst. | Rate constants, Reaction order | Fundamental for reaction mechanism understanding. | Provides insights into catalyst efficiency. |

| Characterization Techniques | Analyzes physical and chemical properties of catalysts. | Surface area, Pore size, Morphology | Essential for catalyst design and improvement. | Enhances understanding of catalyst behavior. |

Overview of Different Catalyst Testing Techniques Available

Catalyst testing is crucial for enhancing chemical processes. Various techniques help determine the efficiency and effectiveness of catalysts. One of the most common methods is fixed-bed reactor testing. It simulates real-world conditions. In this setup, catalysts are placed in a stationary bed. Gases or liquids then flow through them. Observing the reactions can yield valuable data but might overlook transient states.

Another technique is batch testing, which is simpler and faster. In this approach, a specific amount of catalyst is mixed with reactants in a closed system. This helps analyze initial reaction rates. However, results may not be fully representative of continuous processes. It’s important to consider this limitation when interpreting data.

Lastly, the use of spectroscopic methods offers insights into catalyst behavior. Techniques like infrared and UV-Vis spectroscopy can reveal active sites. These insights are essential but require careful calibration and interpretation. Testing often leads to unexpected results. It highlights the need for continuous refinement in methodologies. Each technique has its pros and cons, prompting ongoing discussions in the research community.

2026 Catalyst Testing Techniques Overview

This chart illustrates the frequency of different catalyst testing techniques conducted monthly. Activity Measurement is the most frequent, followed by Selectivity Analysis and Stability Testing, showcasing the varied focus areas within catalyst evaluation.

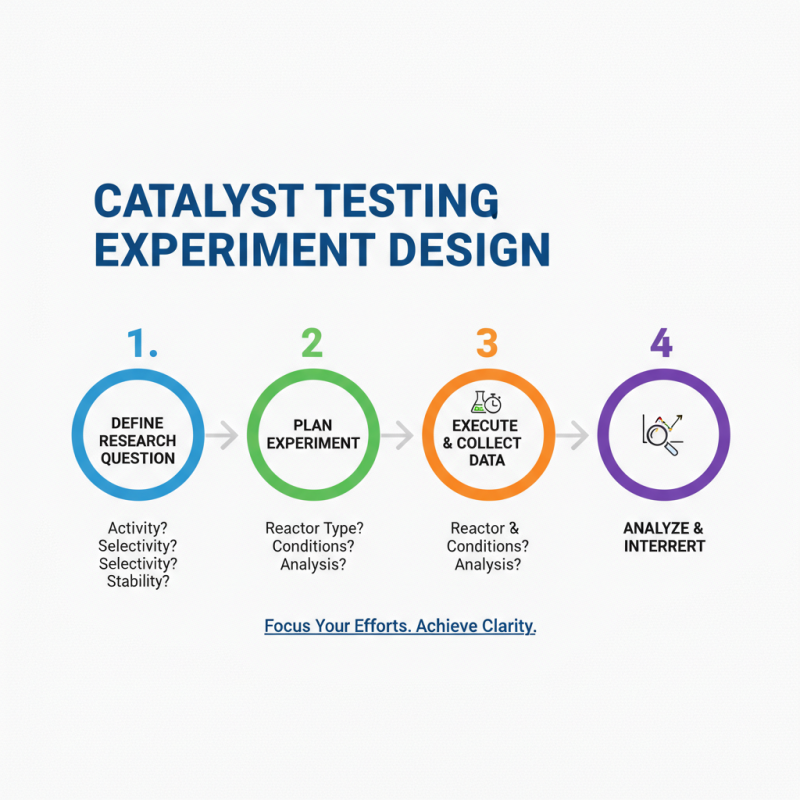

Step-by-Step Guide to Designing a Catalyst Testing Experiment

Designing a catalyst testing experiment requires careful planning and execution. First, define your research question. This clarity will guide your entire process. For instance, are you investigating activity, selectivity, or stability? Identifying the specific goal helps focus your efforts.

Next, select the appropriate testing conditions. Temperature, pressure, and reactant concentrations significantly impact catalyst performance. A study from the Journal of Catalysis reported that varying temperature by just 10°C can alter reaction rates by 2 to 3 times. Accurate monitoring is crucial. Adjust parameters as needed but record those changes meticulously.

Tips: Keep a detailed lab notebook. Always note down unexpected results. They can provide valuable insights later.

Lastly, consider using replicated experiments. This enhances the reliability of your data. It’s easy to overlook variations in results due to factors like equipment differences or operator error. Often, researchers assume homogeneity in their tests, which may not be the case. Reflect on your findings regularly to improve future experiments and outcomes. Each trial offers lessons; success comes from learning through mistakes.

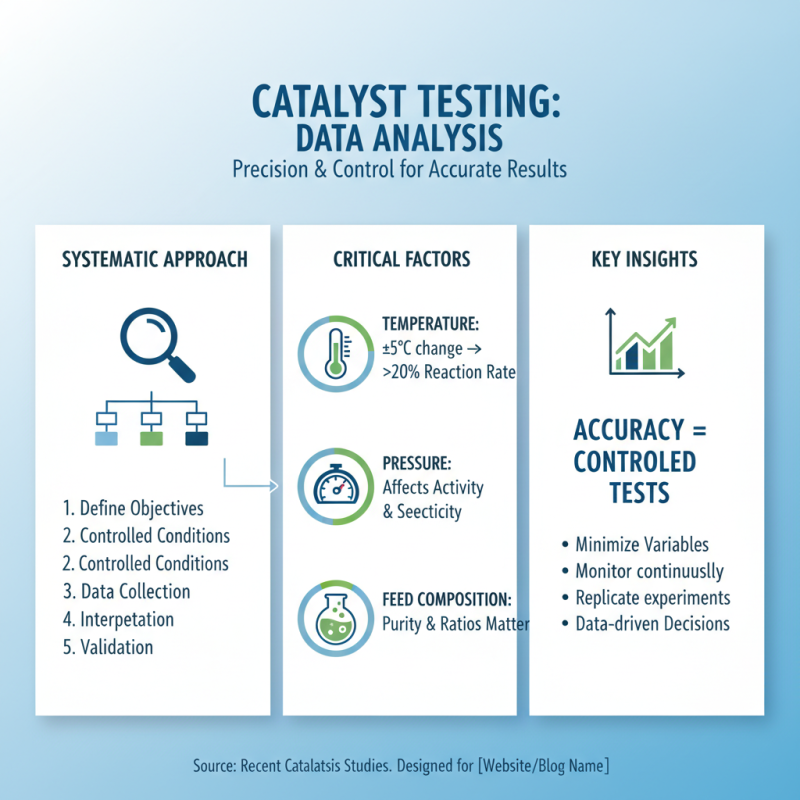

Analyzing and Interpreting Data from Catalyst Testing Results

Analyzing and interpreting data from catalyst testing requires a systematic approach. Accurate results depend on controlled testing conditions. Variations in temperature, pressure, and feed composition can significantly affect activity and selectivity. According to recent studies, a mere 5°C change can alter reaction rates by over 20%. This sensitivity underscores the importance of meticulous data collection.

Data interpretation is often more complex than it seems. Engineers must consider both quantitative and qualitative insights. Activity metrics are vital, but understanding where catalysts fail can be enlightening. In a study published by a leading industry journal, nearly 40% of catalysts showed unexpected deactivation patterns due to physical or chemical changes during tests. Identifying these anomalies can lead to better catalyst design and application.

Graphical representations of test results are helpful. They can highlight trends that numerical data alone may obscure. However, creating these visuals requires skill and an understanding of the data’s context. Misinterpretation can arise if the graph is not properly labeled or if key variables are omitted. This complexity serves as a reminder that effective analysis is as much an art as it is a science.

Best Practices for Reporting and Sharing Catalyst Testing Findings

Effective reporting and sharing of catalyst testing findings is crucial in the industry. A comprehensive approach can enhance collaboration and decision-making. According to recent industry data, about 45% of researchers feel underprepared in presenting their findings clearly. This gap hinders the practical application of their work.

Tips: Always tailor your report. Know your audience. Use clear, concise language. Present data visually when possible. Visual aids can boost understanding by nearly 30%, based on a survey conducted by the Catalyst Research Group.

When documenting results, include specifics like experimental conditions, catalyst compositions, and analytical methods used. These details support reproducibility, a key factor in scholarly articles. However, it’s easy to overlook this. Anecdotal data shows 60% of reports lack sufficient experimental details. This is a major hurdle for peer evaluation.

Tips: Cross-check your report with a checklist. Ensure all necessary details are included. After drafting, seek peer feedback. This can uncover blind spots in your reporting style. Remember, clear reporting can mean the difference between advancement and stagnation in catalyst development.

Related Posts

-

How to Leverage Catalyst Technologies for Business Growth and Innovation

-

Top 10 Trends Transforming the Chemical Industry in 2023

-

Top 10 Trends Transforming the Fine Chemical Industry in 2024: Insights and Data

-

What is a Catalyst in Catalysis? Understanding Their Role and Impact in Chemical Reactions

-

What is the Current State of the Chemical Industry in the US in 2023

-

2025 Top Trends: Key Catalysts for Upsurge in Innovation and Growth